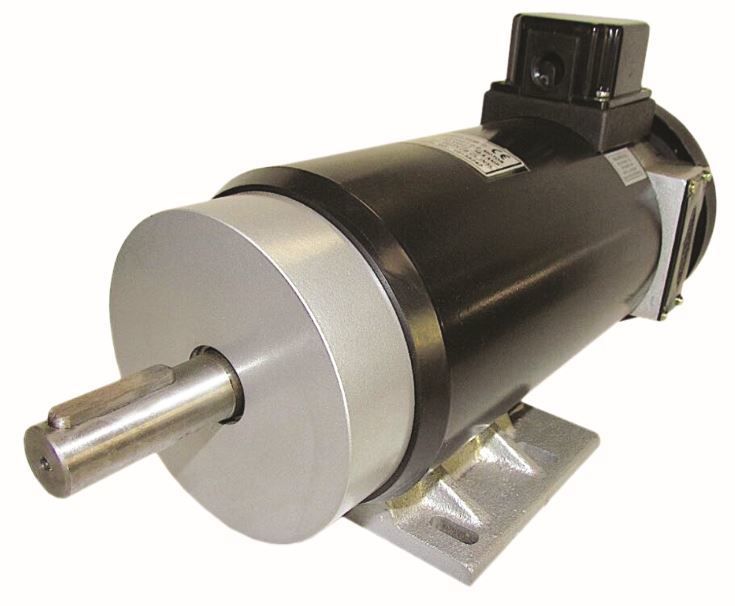

Inline Geared Motor

Inline Geared Motor Specification

- Horse Power

- 0.25 HP 10 HP

- Cooling Method

- Surface cooling

- Efficacy

- IE2/High Efficiency

- Bearing Type

- Deep Groove Ball Bearing

- Sealed Type

- IP55

- Noise Level

- < 70 dB

- Current Type

- AC

- Poles Number

- 2 / 4 / 6 poles

- Voltage

- 220-240V

- Rated Frequency

- 50 Hz

- Rated Voltage

- 230V

- Power Rating

- 0.18 kW 7.5 kW

- Torque

- 20 Nm 800 Nm (varies by model)

- Pressure

- Standard Atmospheric

- Motor Type

- Inline Geared Motor

- Ambient Temperature

- -15C to 45C

- Product Type

- Other

- Output Power

- 0.18 kW 7.5 kW

- Frequency (MHz)

- 50

- Protect Feature

- Totally Enclosed Fan Cooled (TEFC)

- Phase

- Single Phase

- Speed

- 1440 RPM / 960 RPM / 720 RPM

- Starting Type

- Electric Start

- Power

- 0.25 HP to 10 HP

- Color

- Blue / Grey

- Dimension (L*W*H)

- 230 mm x 150 mm x 170 mm (approximate, varies by model)

- Weight

- 6.00 Kilograms (kg)

- Shaft Diameter

- 18 mm 40 mm

- Mounting Type

- Foot / Flange Mounting

- IP Rating

- IP55

- Vibration Level

- 2.8 mm/s

- Output Shaft Type

- Solid / Hollow

- Life Expectancy

- >20,000 Hours

- Gear Ratio

- 3:1 to 200:1

- Lubrication

- Synthetic Oil Filled

- Relative Humidity

- 90%

- Insulation Class

- F

- Efficiency

- 85% - 90%

- Control

- Manual / VFD Compatible

- Duty Cycle

- S1 (Continuous)

- Material

- Cast Iron / Aluminum Housing

- Application

- Conveyor, Packaging, Textile, Industrial Automation

Inline Geared Motor Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 20 Boxes Per Week

- Delivery Time

- 2-3 Week

- Main Domestic Market

- All India

- Certifications

- CE Certified

About Inline Geared Motor

Provided Inline Geared Motor uses basic principles of speed reduction for increasing torque or force. This motor adds mechanical gears for altering speed or torque of it. Offered motor finds its applications in cranes and other related applications. Provided motor uses a very low rotational output speed to create incredible amounts of torque. In addition, offered Inline Geared Motor is available in different specifications according to requirements of clients. It is known for its trouble free functionality.

Key Points:

- Require minimum maintenance

- Sturdy construction

- Power efficient in nature

High-Efficiency Performance

With an efficiency range of 85%% to 90%%, this inline geared motor maximizes energy savings for continuous operations. IE2 certification and totally enclosed fan-cooled (TEFC) protection guarantee robust performance across industrial environments. The advanced surface cooling design ensures thermal consistency, contributing to low noise levels and minimal vibration during operation.

Versatile Application & Control

Designed for adaptability, the inline geared motor serves a spectrum of industries such as packaging, textiles, conveyors, and automation. Users can select between manual or VFD-controlled operation, while the motors gear ratio versatility (3: 1 to 200: 1) provides the right output for specific task requirements. Solid and hollow output shaft options further expand installation possibilities.

Durability and Reliability Assured

Crafted from durable cast iron or aluminum housing with synthetic oil lubrication and deep groove ball bearings, this motor is built for lasting performance. Suitable for harsh conditions with up to 90%% relative humidity and IP55 protection, its engineered for a life expectancy surpassing 20,000 hours, making it a reliable choice for continuous duty cycles.

FAQs of Inline Geared Motor:

Q: How is the Inline Geared Motor installed for different applications?

A: Installation is flexible thanks to foot or flange mounting options and a choice between solid or hollow output shafts. This allows integration into various setups, including conveyor lines, textile machinery, and automated packaging systems.Q: What advantages does the synthetic oil lubrication provide?

A: Synthetic oil lubrication significantly reduces wear and tear, resulting in lower maintenance needs and enhancing the motors life expectancy beyond 20,000 hours, even during continuous S1 duty cycles.Q: Where can this geared motor be used effectively?

A: It excels in industrial automation, packaging, textile, and conveyor applications, delivering consistent performance in environments with ambient temperatures from -15C to 45C and relative humidity up to 90%%.Q: What is the process for controlling the motor speed and functionality?

A: Speed and operational control can be managed manually or integrated with variable frequency drives (VFDs), providing tailored speed adjustment to suit specific operational requirements with available speeds of 1440 RPM, 960 RPM, and 720 RPM.Q: How does the motor design contribute to its reliable operation?

A: The motors cast iron or aluminum housing, deep groove ball bearings, synthetic oil lubrication, and totally enclosed fan cooling (TEFC) collectively ensure smooth, reliable, and quiet operation with minimal vibration ( 2.8 mm/s) and noise (< 70 dB).Q: What benefits can users expect from the IE2/high efficiency rating?

A: IE2-rated high efficiency means reduced energy consumption, lower operating costs, and less heat generation, making the motor both eco-friendly and economical for long-term industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial PMDC Motor Category

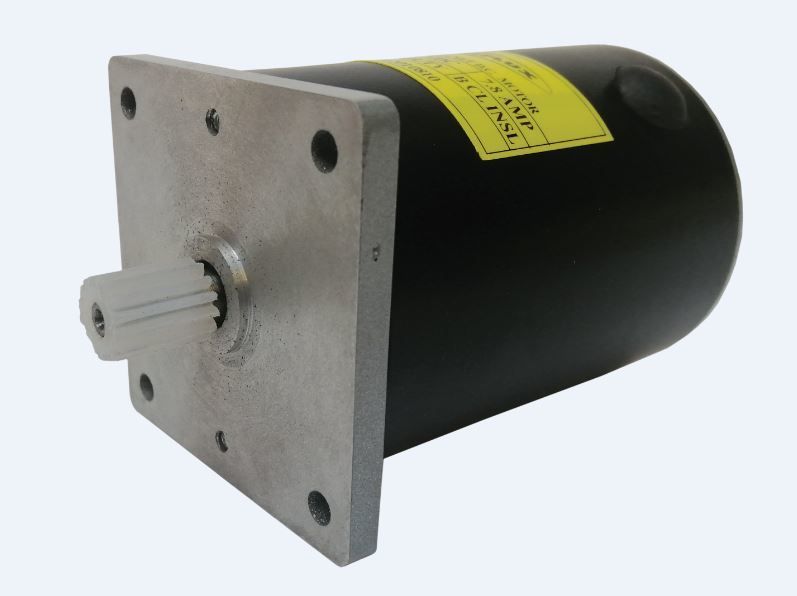

Foot Mount PMDC Motor

Minimum Order Quantity : 1 Box

IP Rating : Other, IP54

Poles Number : 4

Product Type : PMDC Motor

Phase : Other, Single Phase / DC

Techno Generator

Minimum Order Quantity : VARIABLE Box

IP Rating : ip23

Poles Number : 4

Product Type : Other, Diesel Generator

Phase : Three Phase

Worm Gear PMDC Motor

Price 15000 INR / Buckle

Minimum Order Quantity : 1 Container

IP Rating : Ip21

Poles Number : 4, 6

Product Type : Asynchronous Motor

Phase : Single Phase

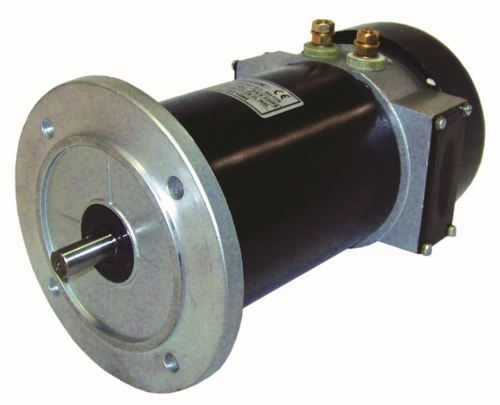

Flange Mount PMDC Motor

Price 15000 INR / Bale

Minimum Order Quantity : VARIABLE Box

IP Rating : Ip21

Poles Number : 4, 6

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS