Arc Mig Welding Thyristerised

Arc Mig Welding Thyristerised Specification

- Current Range

- 60A - 500A (variant wise)

- Diameter

- 0.8 mm to 1.2 mm (wire) or 2.5 mm to 6 mm (electrode)

- Power Source

- Electric Thyristorised Control

- Automation Grade

- Semi-Automatic / Manual

- Frequency

- 50 Hz

- Application

- Fabrication, Heavy Engineering, Structural Welding

- Welding

- GMAW (MIG) / SMAW (Arc)

- Equipment Type

- Arc Mig Welding Thyristerised

- Power Consumption

- Efficient, model dependent

- Output Voltage

- 18-46V

- Phase

- Three Phase

- Type

- Arc MIG Welding Machine Thyristorised

- Condition

- New

- Motor Type

- No Motor (Solid State Control)

- Material

- Heavy Duty Metal Body

- Power

- Varies by Model (typically 8-20 kVA)

- Voltage

- 415 V

- Dimensions

- 850 x 500 x 750 mm (approx.)

- Input Voltage

- 415V 15%, 3 Phase

- Rated Current

- 250A / 400A / 500A depending on model

- Rated Capacity

- Up to 100% Duty Cycle (model dependent)

- Control Panel

- Digital / Analog with preset and display

- Enclosure Protection

- IP21

- Insulation Class

- Class H

- Welding Process

- MIG/ARC (GMAW/SMAW)

- Safety Features

- Overload, Overheating & Short Circuit protection

- Display

- Digital Ammeter & Voltmeter

- Open Circuit Voltage

- 68V - 75V

- Mobility

- Mounted on castor wheels

- Cooling Type

- Forced Air

- Efficiency

- Above 85%

- Terminal

- Heavy copper terminals for input/output cables

- Wire Feeder

- Compatible (optional attachment)

Arc Mig Welding Thyristerised Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Per Week

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Arc Mig Welding Thyristerised

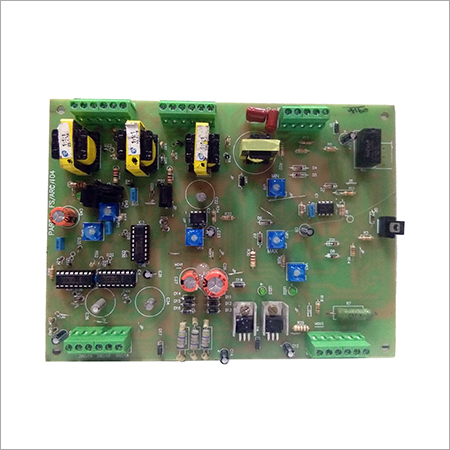

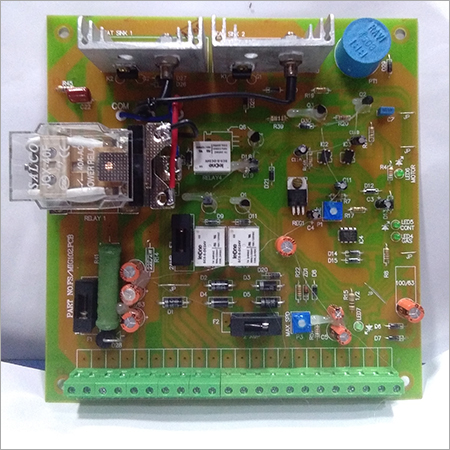

We have been engaged in offering supreme grade Arc Welding pcb, that is known forits hassle-free functionality. This card is mainly used to be installed in thyristerised arc welding machines for operating them in a smooth manner. Offered this card is widely cherished among clients due to its robustness and power efficient nature. In addition tothis, provided Arc Welding can be purchased from us in different specifications (3 scrs & 6 scrs) as per clients demand.

Advanced Welding Control and Ease of Use

This thyristorised welding machine features both digital and analog control panels, enabling precise adjustments of current and voltage settings. The included digital displays allow easy monitoring for greater welding accuracy and repeatability. Whether selecting preset parameters or customizing to project requirements, operators benefit from user-intuitive controls.

Safety and Durability Built In

The heavy-duty metal construction, insulation class H, and forced air cooling ensure the machine performs reliably under rigorous conditions. Integrated safety mechanisms protect against overload, overheating, and short circuit, while the IP21 enclosure and robust terminals add further assurance during extended operations.

Versatile Applications and Maximum Efficiency

Supporting both GMAW (MIG) and SMAW (ARC) processes, this machine delivers versatility for a range of industrial welding needs. With efficiency above 85% and compatibility with wire feeders and electrodes of varying sizes, it is designed for sustained heavy-duty performance and minimal energy wastage.

FAQs of Arc Mig Welding Thyristerised:

Q: How does the thyristorised Arc MIG Welding Machine enhance welding efficiency?

A: With its solid-state thyristor control, the machine provides consistent and reliable output, ensuring high arc stability and reduced energy consumption. Efficiency ratings above 85% mean more of your input power is effectively used for welding, contributing to lower operational costs in the long run.Q: What welding processes can this machine handle?

A: This equipment supports both GMAW (MIG) and SMAW (ARC) welding processes. It allows for seamless switching between modes, making it ideal for diverse industrial and structural welding projects where both processes are required.Q: When is it beneficial to use the digital/analog control panel?

A: Digital/analog control panels are advantageous when precise control over welding parameters is necessary. The presetting features, along with the digital ammeter and voltmeter, assist operators in maintaining accuracy and consistency, particularly in fabrication and heavy engineering applications.Q: Where can this welding machine be ideally used?

A: Thanks to its heavy-duty build, high-duty cycle capability, and mobility on castor wheels, the machine is well-suited for factories, fabrication workshops, construction sites, and maintenance units engaged in large-scale metal joining and structural welding tasks.Q: What is the process for attaching a wire feeder to this machine?

A: This thyristorised welding machine is engineered for compatibility with optional wire feeders. Users can easily attach the feeder to enhance the MIG welding function, facilitating handling of wire diameters from 0.8 mm to 1.2 mm and accommodating various project requirements.Q: How does the machine ensure operator and equipment safety during usage?

A: It features multiple built-in safety mechanisms, including protection against overload, overheating, and short-circuiting. The IP21-rated enclosure and robust insulation (Class H) further safeguard against environmental and operational hazards, ensuring safe and reliable functioning.Q: What are the benefits of using heavy copper terminals and a forced air cooling system in this machine?

A: Heavy copper terminals reduce resistance, ensuring efficient transmission of power to the welding cables. The forced air cooling system dissipates heat effectively, helping maintain stable temperatures even during extended use, thereby prolonging the machines life and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Machine Control PCB Category

Mig Welding Card (Model 3)

Price 2000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Welding : Other, For MIG Welding Operation

Condition : New

Automation Grade : SemiAutomatic / Automatic

Material : High Grade PCB, Electronic Components

Spot Welding Timer

Price 50000 INR / Billions Of Unit

Minimum Order Quantity : 1 , , Bottle

Welding : Other, Suitable for Spot Welding Applications

Condition : New

Automation Grade : SemiAutomatic/Automatic

Material : Metal Enclosure

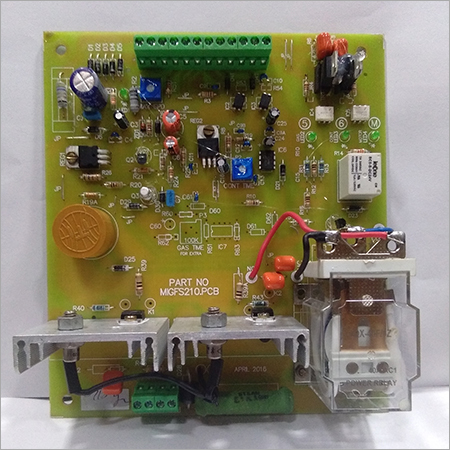

MIG Welding Wire Feeder Card (Model 1)

Welding : Other, GMAW (MIG)

Condition : New

Automation Grade : Semi Automatic

Material : HighGrade PCB and Electronic Components

Mig Welding Card (Model 2)

Welding : Other, MIG Welding

Condition : New

Automation Grade : Manual / SemiAutomatic

Material : Industrial Grade Components

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS