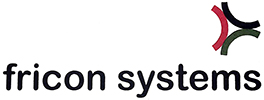

Mig Welding Card (Model 3)

Price 2000 INR/ Piece

MOQ : 1 , , Piece

Mig Welding Card (Model 3) Specification

- Automation Grade

- Semi-Automatic / Automatic

- Frequency

- 50/60 Hz

- Power Consumption

- Optimized for Energy Efficiency

- Power Source

- Electric

- Current Range

- 50 - 600 A

- Application

- Industrial MIG Welding Machines

- Phase

- Single/Three Phase

- Welding

- For MIG Welding Operation

- Output Voltage

- 24 V DC (Control Output)

- Equipment Type

- Electronic Welding Controller Board

- Type

- Mig Welding Card

- Condition

- New

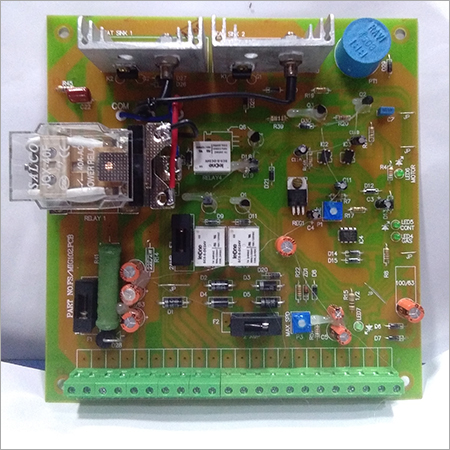

- Motor Type

- DC/AC Compatible

- Material

- High Grade PCB, Electronic Components

- Power

- Suitable for 3 Phase/440V

- Voltage

- 415 V

- Dimensions

- 208 mm x 135 mm (approx)

- Input Voltage

- 220 V AC / 440 V AC

- Rated Current

- Depends on Welding Machine Model

- Rated Capacity

- Customized, typically 16-32A

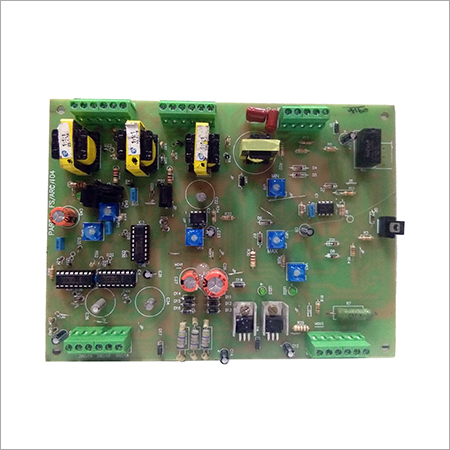

- Display

- LED Status Indicators

- Maintenance

- Low-maintenance design with replaceable relays/IC

- Compatible Welding Machines

- Most standard MIG welding machines

- Weight

- 1.25 kg (approx)

- Mounting Type

- Panel Mount/Chassis Mount

- Control Features

- Wire Feed and Welding Current Regulation

- PCB Finish

- Coated for durability and heat resistance

- Safety Features

- Overload Protection, Short Circuit Protection

- Cooling

- Requires external fan-based or machine cooling

- Life Cycle

- Designed for continuous operation

Mig Welding Card (Model 3) Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Mig Welding Card (Model 3)

Step up to elite welding performance with the blue-ribbon Mig Welding Card (Model 3). Designed for first-string reliability, its compatible with most standard MIG welding machines and boasts a paragon PCB finish for heat resistance. With precise control featureslike wire feed and current regulationLED status indicators, and robust overload protection, this panel/chassis mount card is the ideal upgrade for semi-automatic or automatic welding. Try now to enjoy a discount on this new, low-maintenance tool, optimized for industrial demands and continuous operation.

Advanced Features and Versatile Applications

Mig Welding Card (Model 3) stands out with extra features such as sophisticated overload and short circuit protection, wire feed precision, and LED status display. Used as an electronic welding controller board, its widely applied in industrial MIG welding machines, suitable for both DC and AC motors. Its low-maintenance, high-grade build ensures reliable operation across various application media, serving as a trusted component for manufacturers, exporters, and service providers.

Domestic Market Reach and Certified Supply Policies

Supplying nationwide, Mig Welding Card (Model 3) maintains a competitive rate for the main domestic market in India. Quotations are provided upon request, and sample policies are available for large-scale buyers. Certified for quality and safety, each unit meets rigorous standards. With flexible support for manufacturers, exporters, and suppliers, businesses can rely on consistent delivery and assured certification compliance.

Advanced Features and Versatile Applications

Mig Welding Card (Model 3) stands out with extra features such as sophisticated overload and short circuit protection, wire feed precision, and LED status display. Used as an electronic welding controller board, its widely applied in industrial MIG welding machines, suitable for both DC and AC motors. Its low-maintenance, high-grade build ensures reliable operation across various application media, serving as a trusted component for manufacturers, exporters, and service providers.

Domestic Market Reach and Certified Supply Policies

Supplying nationwide, Mig Welding Card (Model 3) maintains a competitive rate for the main domestic market in India. Quotations are provided upon request, and sample policies are available for large-scale buyers. Certified for quality and safety, each unit meets rigorous standards. With flexible support for manufacturers, exporters, and suppliers, businesses can rely on consistent delivery and assured certification compliance.

FAQs of Mig Welding Card (Model 3):

Q: How is the Mig Welding Card (Model 3) installed with MIG welding machines?

A: The Mig Welding Card (Model 3) offers versatile panel or chassis mounting, making it easy to integrate with most standard MIG welding machines.Q: What safety features does this controller board offer?

A: This model comes with built-in overload and short circuit protection, ensuring the safety of both users and equipment during operation.Q: When should the external fan or machine cooling be connected?

A: External cooling is required and should be connected whenever the card is in use, particularly during continuous or high-load welding tasks.Q: Where is this welding controller board most commonly used?

A: Its predominantly used in industrial sectors requiring MIG welding, such as manufacturing plants, fabrication workshops, and automation lines.Q: What is the process to request a quotation or sample for bulk supply?

A: To request a rate or quotation and sample, simply contact the supplier or manufacturer directly and specify your requirements for timely assistance.Q: How does the card benefit ongoing operations and maintenance?

A: Designed for continuous operation, it reduces downtime with a low-maintenance design and features easily replaceable relays and ICs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Machine Control PCB Category

Spot Welding Timer

Price 50000 INR / Billions Of Unit

Minimum Order Quantity : 1 , , Bottle

Welding : Other, Suitable for Spot Welding Applications

Condition : New

Output Voltage : Relay Contacts/Trigger Output

Automation Grade : SemiAutomatic/Automatic

Arc Mig Welding Thyristerised

Welding : Other, GMAW (MIG) / SMAW (Arc)

Condition : New

Output Voltage : 1846V

Automation Grade : SemiAutomatic / Manual

MIG Welding Wire Feeder Card (Model 1)

Welding : Other, GMAW (MIG)

Condition : New

Output Voltage : DC Output as per feeder requirement

Automation Grade : Semi Automatic

Mig Welding Card (Model 2)

Welding : Other, MIG Welding

Condition : New

Output Voltage : 24V DC

Automation Grade : Manual / SemiAutomatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS