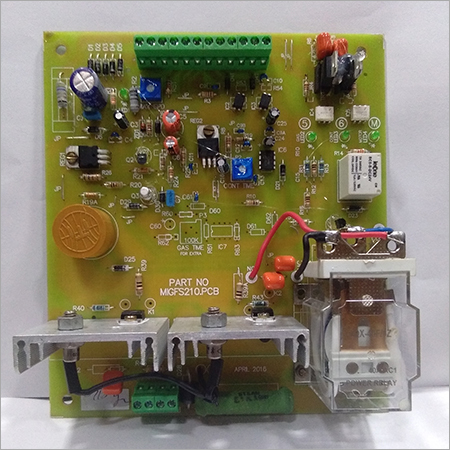

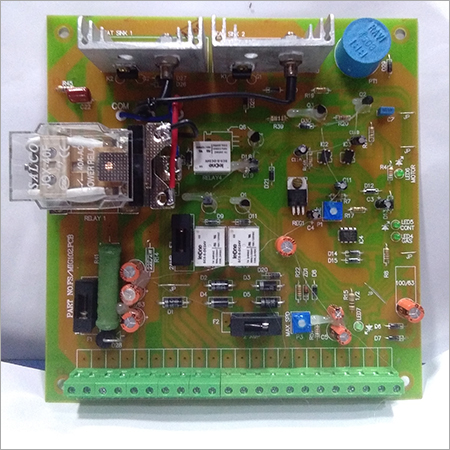

Mig Welding Card (Model 2)

Mig Welding Card (Model 2) Specification

- Automation Grade

- Manual / Semi-Automatic

- Frequency

- 50Hz

- Output Voltage

- 24V DC

- Phase

- Single Phase

- Power Consumption

- Low

- Welding

- MIG Welding

- Diameter

- Fits standard MIG units

- Equipment Type

- MIG Welding Spare Electronic Control Card

- Power Source

- Electric

- Application

- MIG Welding Machines, Industrial Welding Automation

- Current Range

- Adjustable as per machine requirement

- Type

- Mig Welding Card

- Condition

- New

- Material

- Industrial Grade Components

- Power

- Universal, Compatible with various MIG machines

- Voltage

- 220V

- Dimensions

- Standard (As per Model 2 specifications)

- Input Voltage

- 220V AC

- Rated Current

- 10A

- Rated Capacity

- Designed for heavy duty welding operations

- Control Functions

- Wire Feed, Burn Back, Crater, Gas Purge, Jog

- Mounting

- Panel/Chassis Mount

- Display

- LED status indicators

- PCB Coating

- Protective, industrial-grade lacquered

- Fuse Protection

- Integrated fuse on input

- Product Code

- Model 2

- Operating Temperature

- 0°C to 55°C

- Compatibility

- Suitable for most branded MIG Welding Machines

- Humidity Tolerance

- Up to 95% non-condensing

- Repairability

- Component-level repair possible

Mig Welding Card (Model 2) Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque

- Main Domestic Market

- All India

About Mig Welding Card (Model 2)

Mig Welding Card (Model 2): Advanced Control for Industrial Welders

Mig Welding Card (Model 2) is designed for precise control and reliability in demanding industrial environments. Its key features include wire feed, burn back, crater, gas purge, jog control, LED status indicators, and panel or chassis mounting options. Used primarily in MIG Welding Machines, it ensures consistent quality with manual or semi-automatic automation. Crafted from industrial-grade materials and compatible with various branded units, it delivers robust performance for heavy-duty operations.

FOB Port, Certifications, and Export Market Success

Mig Welding Card (Model 2) is supplied from major FOB ports in India, ensuring quick dispatch and reliable handover to international clients. The product is certified to meet stringent industrial standards, reinforcing its reliability in export markets like Asia, Africa, and the Middle East. As an exporter, manufacturer, supplier, and service provider, we emphasize efficiency and secure transactions for our global customer base, helping industries scale their operations effortlessly.

FAQs of Mig Welding Card (Model 2):

Q: How is the Mig Welding Card (Model 2) installed in MIG Welding Machines?

A: Mig Welding Card (Model 2) is designed for panel or chassis mounting, allowing easy integration into most branded MIG Welding Machines by following standard installation procedures as specified in the manual.Q: What functions does the Mig Welding Card (Model 2) control during welding operations?

A: The card manages essential controls such as wire feed, burn back, crater, gas purge, and jog, providing accurate operation for both manual and semi-automatic MIG welding processes.Q: Where can this welding control card be used most effectively?

A: This card is ideal for use in industrial MIG Welding Machines and automation systems, fitting standard units and accommodating rigorous environments due to its protective coating and robust construction.Q: When is component-level repair possible for Mig Welding Card (Model 2)?

A: Component-level repair is achievable when individual parts of the card are damaged, rather than the entire card needing replacement, helping reduce maintenance costs and downtime.Q: What are the main benefits of using this card in welding applications?

A: Key benefits include improved operational efficiency, enhanced safety via integrated fuse protection, adjustable current range, and durability from industrial-grade components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Machine Control PCB Category

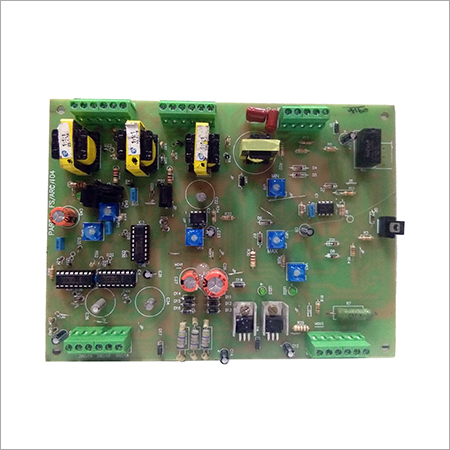

Mig Welding Card (Model 3)

Price 2000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Welding : Other, For MIG Welding Operation

Condition : New

Power : Suitable for 3 Phase/440V

Rated Current : Depends on Welding Machine Model

Arc Mig Welding Thyristerised

Welding : Other, GMAW (MIG) / SMAW (Arc)

Condition : New

Power : Varies by Model (typically 820 kVA)

Rated Current : 250A / 400A / 500A depending on model

Spot Welding Timer

Price 50000 INR / Billions Of Unit

Minimum Order Quantity : 1 , , Bottle

Welding : Other, Suitable for Spot Welding Applications

Condition : New

Power : 510 W (Control Circuit)

Rated Current : Up to 50A (Switching Capability)

MIG Welding Wire Feeder Card (Model 1)

Welding : Other, GMAW (MIG)

Condition : New

Power : Low Power Consumption

Rated Current : Up to 10A

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS