Spot Welding Timer

Price 50000 INR/ Billions Of Unit

Spot Welding Timer Specification

- Output Voltage

- Relay Contacts/Trigger Output

- Automation Grade

- Semi-Automatic/Automatic

- Current Range

- User Adjustable

- Frequency

- 50/60 Hz

- Equipment Type

- Timer Controller for Spot Welding

- Phase

- Single Phase

- Application

- Spot Welding Machine, Welding Automation

- Welding

- Suitable for Spot Welding Applications

- Power Consumption

- Very Low (Control Unit)

- Power Source

- Electric

- Type

- Spot Welding Timer

- Condition

- New

- Material

- Metal Enclosure

- Power

- 5-10 W (Control Circuit)

- Voltage

- 220-240 V

- Dimensions

- Approx. 180mm x 115mm x 70mm

- Input Voltage

- 220 V AC

- Rated Current

- Up to 50A (Switching Capability)

- Rated Capacity

- As per model specification

- Relay Output

- 1 NO + 1 NC, Heavy Duty

- Operating Temperature

- 0°C to 55°C

- Timer Range

- 0~99 cycles or seconds, adjustable

- Display Type

- Digital/LED Display

- Mounting Type

- Panel/Wall Mount

- Control Method

- Microcontroller Based

- Weight

- Approx. 750 g

- Protection Features

- Overload and Short Circuit Protection

- Switching Device

- Solid State Relay or Electromechanical Relay

- Indication

- LED Status Indicator

Spot Welding Timer Trade Information

- Minimum Order Quantity

- 1 , , Bottle

- Payment Terms

- Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

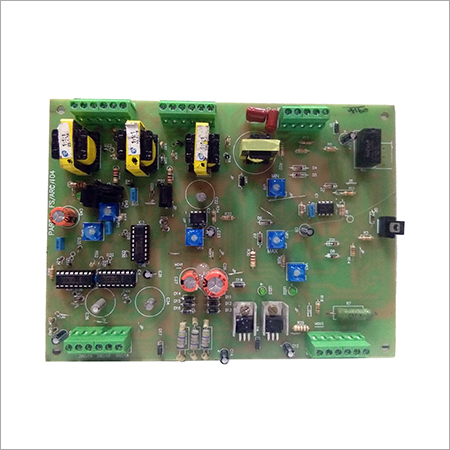

About Spot Welding Timer

It consist of two digit digital spot welding timer with output of 220 volt solenoid valve & contractor. It is used to control spot welding machine.It has a stable welding quality.

-

The primary function is to accurately regulate the time the welding current is active, known as the "weld time" or "spot time".

-

By providing precise, repeatable weld times, the timer helps maintain stable welding quality and consistent weld bead length across multiple welds.

Accurate Timing for Spot Welding Applications

The Spot Welding Timer Controller ensures optimal welding results by providing customizable timing with a range from 0 to 99 cycles or seconds. The digital LED display allows for intuitive parameter adjustments and clear status indicators, making it suitable for various spot welding automation setups.

Robust Safety and Protection Mechanisms

With built-in overload and short circuit protection, this controller is designed for demanding industrial use. Its heavy-duty metal enclosure and reliable relay outputoffering both normally open and normally closed contactssafeguard your equipment and maintain operational integrity under harsh conditions.

Versatile Mounting and User-Friendly Operation

Designed for both panel and wall mounting, this timer controller can adapt to a wide range of workspaces. Easy installation and microcontroller-based control make it accessible to operators, while low power consumption ensures cost-efficient performance in diverse manufacturing environments.

FAQs of Spot Welding Timer:

Q: How is the timer range adjusted on the Spot Welding Timer Controller?

A: The timer range can be easily set between 0 and 99 cycles or seconds using the control panel buttons. The digital LED display provides real-time feedback, enabling precise adjustments for your specific welding application.Q: What types of relays are supported by this controller?

A: The timer supports both solid-state and electromechanical relays for output switching. It offers 1 normally open (NO) and 1 normally closed (NC) contact, providing flexibility for different welding machine configurations.Q: Where can this Spot Welding Timer Controller be mounted?

A: This controller is designed for convenient installation; it can be mounted on a panel or directly onto a wall, depending on workspace requirements and machine layout.Q: What benefits does the microcontroller-based control offer?

A: Microcontroller-based operation enables high-precision timing, reliable automation, and consistent repeatability, ensuring each spot weld is executed with accuracy and enhancing overall productivity.Q: When should I use the overload and short circuit protection features?

A: These protection features are always active and safeguard your equipment from potential electrical faults, making the controller safe for continuous use in demanding industrial environments.Q: What applications is this Spot Welding Timer suitable for?

A: This timer is ideal for spot welding machines in various industries, including automation-grade production lines, repair workshops, and manufacturing units requiring consistent weld quality and timing control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Machine Control PCB Category

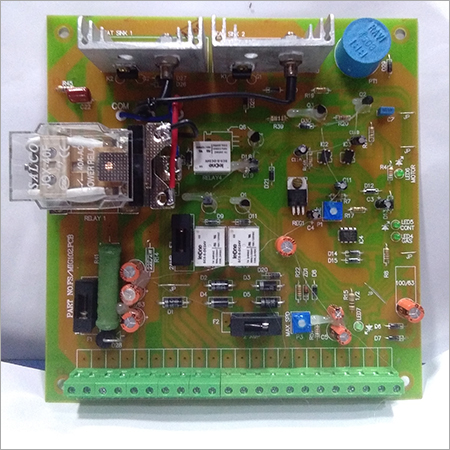

Mig Welding Card (Model 3)

Price 2000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Welding : Other, For MIG Welding Operation

Condition : New

Phase : Single/Three Phase

Equipment Type : Electronic Welding Controller Board

Arc Mig Welding Thyristerised

Welding : Other, GMAW (MIG) / SMAW (Arc)

Condition : New

Phase : Three Phase

Equipment Type : Arc Mig Welding Thyristerised

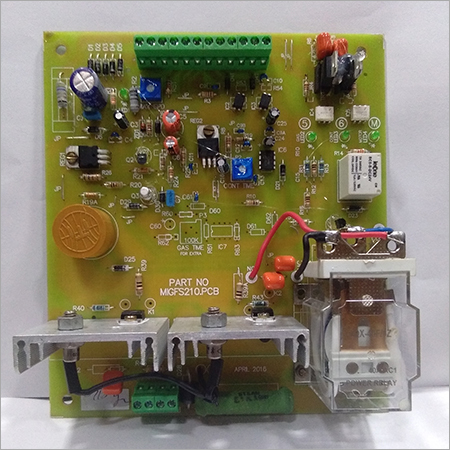

MIG Welding Wire Feeder Card (Model 1)

Welding : Other, GMAW (MIG)

Condition : New

Phase : Single Phase

Equipment Type : MIG Welding Wire Feeder PCB Card

Mig Welding Card (Model 2)

Welding : Other, MIG Welding

Condition : New

Phase : Single Phase

Equipment Type : MIG Welding Spare Electronic Control Card

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS