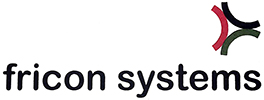

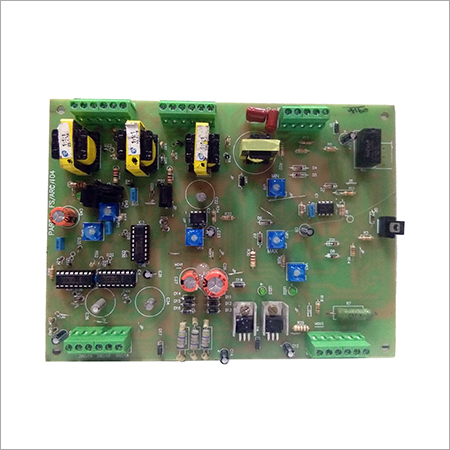

Projection Welding Controller & Firing Card

Price 15000 INR/ Bale

Projection Welding Controller & Firing Card Specification

- Welding

- MIG

- Condition

- New

- Motor Type

- AC Motor

Projection Welding Controller & Firing Card Trade Information

- Minimum Order Quantity

- 1 Bottle

- Payment Terms

- Cash in Advance (CID), Cheque

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Projection Welding Controller & Firing Card

It consist of two digit digital spot welding timer with output of 220 volt with 2 solenoid valve & including control of current bySCRs. It consist the store parameter up to 12 jobs. We provide display with LCD based.

-

To execute the complete projection welding process by controlling the sequence of operations, including current application, pressure application, and timing.

-

- Parameter Control: Accurately regulates welding current, voltage, and duration for optimal weld quality.

- Process Sequencing: Manages the entire welding cycle, from electrode movement to the final solidification of the weld.

- User Interface: Often includes a user-friendly interface for setting and monitoring weld parameters.

- Automation: Facilitates automated and repetitive welding operations, ensuring consistency across multiple welds.

- Parameter Control: Accurately regulates welding current, voltage, and duration for optimal weld quality.

-

To provide the precise and reliable control signals to the power switching components (like SCRs) that deliver the welding current.

-

- Thyristor/SCR Triggering: Generates the gate pulses needed to 'fire' SCRs, allowing them to conduct current at the appropriate moment.

- Synchronized Operation: Ensures that the firing of the SCRs is synchronized with the welding process, leading to smooth and controlled current delivery.

- Power Regulation: Contributes to the precise control of the welding current by precisely timing when the SCRs turn on and off.

- Integration: Seamlessly integrates with the welding controller to provide the necessary signals for accurate and repeatable welds.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Machine Control PCB Category

Mig Welding Card (Model 3)

Price 2000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Welding : Other, For MIG Welding Operation

Current Range : 50 600 A

Dimensions : 208 mm x 135 mm (approx)

Automation Grade : SemiAutomatic / Automatic

Arc Mig Welding Thyristerised

Welding : Other, GMAW (MIG) / SMAW (Arc)

Current Range : 60A 500A (variant wise)

Dimensions : 850 x 500 x 750 mm (approx.)

Automation Grade : SemiAutomatic / Manual

Spot Welding Timer

Price 50000 INR / Billions Of Unit

Minimum Order Quantity : 1 , , Bottle

Welding : Other, Suitable for Spot Welding Applications

Current Range : User Adjustable

Dimensions : Approx. 180mm x 115mm x 70mm

Automation Grade : SemiAutomatic/Automatic

MIG Welding Wire Feeder Card (Model 1)

Welding : Other, GMAW (MIG)

Current Range : Compatible with 250A400A Range

Dimensions : 110 mm x 70 mm (Approx)

Automation Grade : Semi Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS